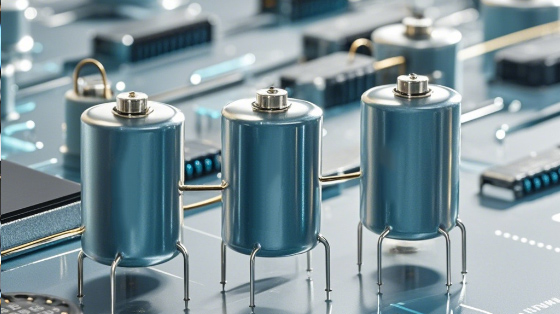

Capacitors: Vital Components in the World of Electronics

10/25/2024 11:42:55 AM

Capacitors are essential passive electronic components that play a crucial role in a wide variety of electrical and electronic circuits. They have the ability to store and release electrical energy, which makes them indispensable in numerous applications, ranging from power supplies and signal processing to communication systems and consumer electronics.

A capacitor is composed of two conductive plates separated by an insulating material called a dielectric. When a voltage is applied across the plates, an electric field is established in the dielectric, and positive and negative charges accumulate on the respective plates. The amount of charge that a capacitor can store is directly proportional to the voltage applied and its capacitance value. Capacitance, measured in farads (F), is a fundamental property of a capacitor and depends on factors such as the area of the plates, the distance between them, and the permittivity of the dielectric material.

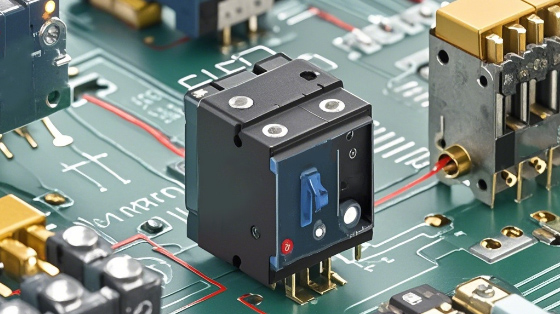

There are several types of capacitors, each with its own unique characteristics and applications. One of the most common types is the ceramic capacitor. Ceramic capacitors are made using a ceramic material as the dielectric. They are available in a wide range of capacitance values and voltage ratings. Ceramic capacitors are known for their small size, low cost, and good stability. They are widely used in high-frequency applications such as in radio frequency (RF) circuits and digital circuits. For example, in a smartphone, ceramic capacitors are used to decouple power supply lines, filter out noise, and stabilize the voltage for various components like microprocessors and integrated circuits.

Another important type is the electrolytic capacitor. Electrolytic capacitors have a much larger capacitance compared to ceramic capacitors and are typically used in applications where a significant amount of energy needs to be stored or filtered. They consist of a metal anode, a cathode made of a conductive electrolyte, and a paper or plastic separator. Electrolytic capacitors are polarized, meaning they have a specific positive and negative terminal, and incorrect polarity connection can lead to damage or even explosion. They are commonly used in power supply circuits to smooth out the rectified direct current (DC) output and reduce ripple voltage. In audio amplifiers, electrolytic capacitors are used to couple different stages of the amplifier and to filter out low-frequency noise.

Tantalum capacitors are another variant that offers a relatively high capacitance in a small package size. They have good temperature and frequency characteristics and are often used in applications where space is limited and stable performance is required. Tantalum capacitors are used in portable electronic devices such as tablets, laptops, and medical implants. However, they are more expensive than ceramic and electrolytic capacitors and have a lower voltage rating.

The construction and manufacturing of capacitors involve precise processes. For ceramic capacitors, the ceramic dielectric is formed into a thin layer, and the conductive plates are deposited or attached to it. The capacitor is then encapsulated to protect it from the environment. In the case of electrolytic capacitors, the anode is typically made of aluminum or tantalum, and the electrolyte is carefully impregnated into a porous material. The manufacturing process requires strict quality control to ensure the proper capacitance value, voltage rating, and reliability of the capacitors.

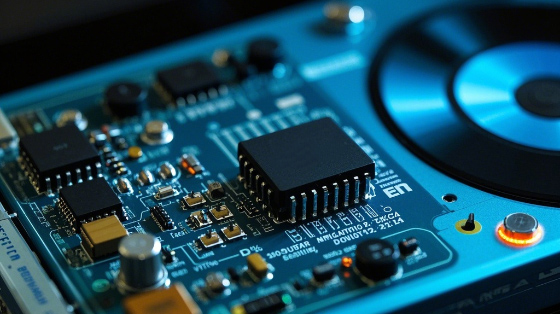

Capacitors have a wide range of applications in different fields. In power electronics, they are used in power factor correction circuits to improve the efficiency of power systems. In motor control circuits, capacitors are used to start and run motors smoothly. In communication systems, capacitors are used in filters to separate different frequency bands and in impedance matching circuits to ensure efficient signal transfer between different components. In consumer electronics, capacitors are found in almost every device, from televisions and refrigerators to cameras and toys.

The performance of capacitors is characterized by several parameters. In addition to capacitance, the voltage rating is a crucial factor. Exceeding the voltage rating can cause the capacitor to break down and fail. The equivalent series resistance (ESR) and equivalent series inductance (ESL) also affect the performance of capacitors, especially in high-frequency applications. A low ESR and ESL are desirable for capacitors used in RF and high-speed digital circuits to minimize power losses and signal distortion.

The future of capacitors looks promising, with ongoing research and development focused on improving their performance and meeting the demands of emerging technologies. One area of interest is the development of high-energy-density capacitors. These capacitors could potentially replace batteries in some applications, such as in hybrid and electric vehicles, where rapid charging and discharging capabilities are required. Research is also being conducted on new dielectric materials with higher permittivity and lower losses, which could lead to the production of smaller and more efficient capacitors.

In conclusion, capacitors are vital components in the world of electronics. Their ability to store and release electrical energy, along with their diverse types and characteristics, makes them essential in countless applications. As technology continues to advance, capacitors will continue to evolve and play an even more significant role in powering and enhancing the performance of electronic devices and systems.

The global capacitor market is highly competitive, with manufacturers constantly striving to improve product quality, reduce costs, and develop new and innovative capacitor technologies. However, the industry also faces challenges such as the need to comply with environmental regulations and the increasing demand for miniaturization and higher performance.

To address these challenges, capacitor manufacturers are investing in research and development to find new materials and manufacturing processes. For example, the development of polymer dielectrics and nanocomposite materials shows potential for improving capacitor performance. Additionally, efforts are being made to optimize the manufacturing process to reduce waste and energy consumption.

In the field of renewable energy, capacitors are used in energy storage systems, such as in solar and wind power installations. They help to smooth out the intermittent power output and improve the stability and reliability of the power grid. In the automotive industry, capacitors are used in various electronic systems, including engine control units, infotainment systems, and advanced driver-assistance systems (ADAS). The demand for capacitors with high temperature and vibration resistance is increasing as vehicles become more electrified and autonomous.

In conclusion, capacitors have a rich history and a bright future. Their importance in different industries and applications cannot be overstated, and continued innovation in this area will be crucial for the development of modern technology.