Relays: The Versatile Switches in Electronic Circuits

10/25/2024 11:39:56 AM

Relays are electromechanical or solid-state devices that have been an integral part of electronic circuits for decades. They serve as electrically controlled switches, enabling the control and isolation of electrical circuits in a wide range of applications, from industrial automation and power systems to automotive electronics and household appliances.

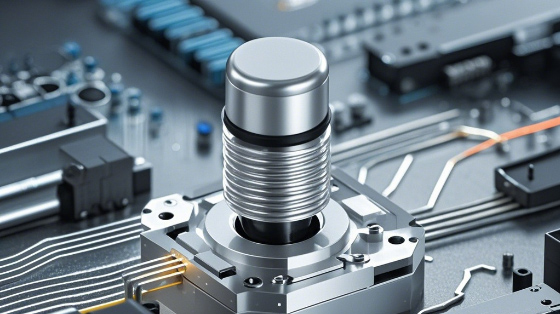

An electromechanical relay consists of an electromagnetic coil, a movable armature, and a set of contacts. When an electric current passes through the coil, it generates a magnetic field that attracts the armature. The movement of the armature causes the contacts to open or close, thereby allowing or interrupting the flow of current in another circuit. The contacts can be normally open (NO), which means they are open when the relay is not energized, or normally closed (NC), which are closed when the relay is at rest. There are also changeover contacts that can perform both functions.

The construction of an electromechanical relay is designed to withstand various electrical and mechanical stresses. The coil is wound around a magnetic core and is insulated to prevent short circuits. The contacts are made of materials with good conductivity and durability, such as silver or silver alloys, and are often plated to improve their performance and resistance to oxidation and corrosion. The housing of the relay protects the internal components and provides mechanical stability.

Electromechanical relays offer several advantages. They can handle relatively high voltages and currents, making them suitable for power control applications. For example, in an industrial motor control circuit, a relay can be used to start, stop, and reverse the motor. They also provide electrical isolation between the control circuit and the load circuit, which is crucial for safety and to prevent interference. Moreover, relays have a simple and reliable operation, and their state (open or closed) can be easily detected and monitored.

However, electromechanical relays also have some limitations. They have a relatively slow switching speed compared to solid-state devices, which can range from a few milliseconds to tens of milliseconds. This makes them less suitable for applications that require high-frequency switching or rapid response times. Additionally, due to the mechanical movement of the contacts, they have a limited lifespan and may experience contact wear and bounce over time. Contact bounce can cause electrical noise and may affect the proper operation of the circuit.

Solid-state relays (SSRs) have emerged as an alternative to electromechanical relays in some applications. SSRs use semiconductor components, such as transistors or thyristors, to perform the switching function. They have no moving parts, which gives them several advantages. SSRs have a much faster switching speed, typically in the microsecond to nanosecond range, making them ideal for applications in high-frequency circuits, such as in communication systems and power supplies for electronic equipment. They also have a longer lifespan and are more resistant to shock and vibration.

However, SSRs also have their own drawbacks. They have a relatively lower current and voltage handling capacity compared to some large electromechanical relays. They also generate more heat during operation, which requires proper heat sinking and thermal management. Additionally, SSRs can be more expensive than electromechanical relays, especially for high-power applications.

Relays are used in a vast number of applications. In industrial automation, relays are used in control panels to control various machines and processes. They can be used to turn on and off pumps, valves, heaters, and other industrial equipment based on signals from sensors or programmable logic controllers (PLCs). In power systems, relays are used for protection and switching. For example, overcurrent relays are used to detect and protect against excessive current in a circuit, and circuit breaker relays are used to trip the circuit breaker in case of a fault.

In automotive electronics, relays are used in the vehicle's electrical system. They are used to control the headlights, windshield wipers, horn, and other electrical components. In household appliances, relays are used in refrigerators, washing machines, air conditioners, and other devices to control the operation of motors, compressors, and heaters.

The selection of a relay for a particular application depends on several factors. These include the required voltage and current ratings, the switching speed, the number of contacts needed, the level of electrical isolation required, and the environmental conditions. For example, in a harsh industrial environment with high temperatures, humidity, and vibration, a relay with a robust construction and good environmental resistance would be preferred.

The future of relays looks towards further improvement and innovation. Research and development efforts are focused on enhancing the performance of both electromechanical and solid-state relays. For electromechanical relays, this includes developing new materials and designs to improve switching speed, reduce contact bounce, and increase lifespan. For solid-state relays, efforts are being made to increase their power handling capacity, improve thermal management, and reduce cost.

In conclusion, relays, whether electromechanical or solid-state, are essential components in electronic circuits. Their ability to control and isolate electrical circuits makes them indispensable in a wide variety of applications. As technology continues to progress, relays will continue to evolve and adapt to meet the changing needs of different industries and applications.

The global relay market is witnessing significant growth due to the increasing demand for automation in various industries. The industrial sector is a major consumer of relays, with the growth of factories and manufacturing plants driving the need for reliable control and protection devices. The automotive industry is also a significant contributor, as the number of electronic components in vehicles continues to rise.

However, the relay industry faces challenges such as the need to comply with stricter environmental and safety regulations. For example, the use of certain hazardous materials in relay manufacturing is being restricted, which requires manufacturers to find alternative materials and manufacturing processes. Additionally, the competition from other switching technologies, such as semiconductor switches and optoelectronic relays, is increasing.

To address these challenges, relay manufacturers are investing in research and development to develop more environmentally friendly and efficient relay technologies. They are also focusing on improving product quality and reliability through better manufacturing processes and quality control. Collaboration between manufacturers, research institutions, and end-users is essential to drive the development of new relay technologies and meet the evolving needs of the market.

In conclusion, relays will continue to be a vital part of the electronics ecosystem, and their continued evolution and improvement are crucial for the advancement of technology in various fields.